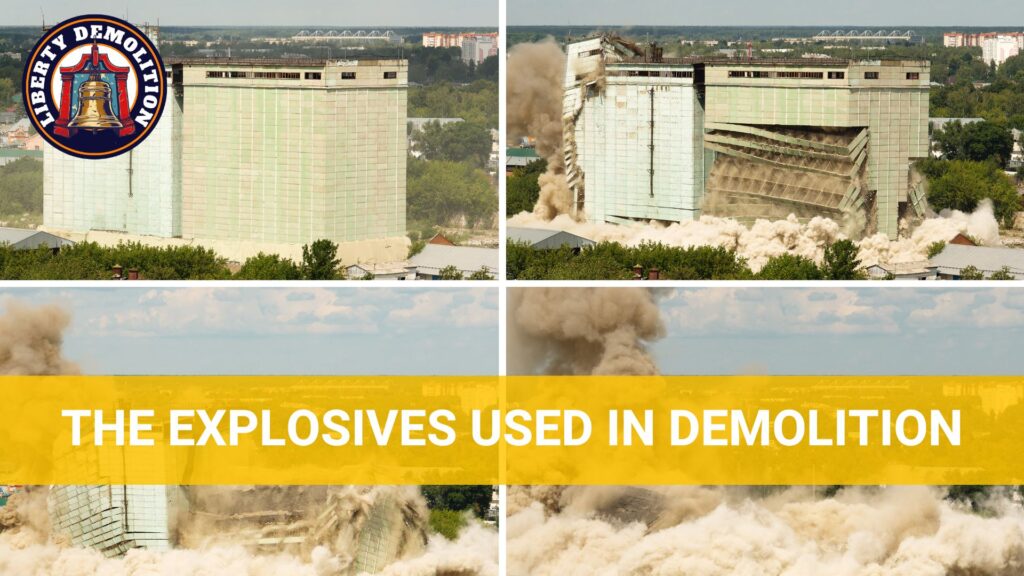

Explosive demolition is the method of using explosives to bring down structures in a controlled and deliberate manner. It’s a specialized technique best suited for large-scale demolitions, especially for tall or massive structures, where traditional methods are impractical or time-consuming.

Curious to know more? Let’s get right through it.

What Is a Method of Demolition that Uses Explosives?

When we think about demolition, images of bulldozers and wrecking balls might come to mind. But in certain circumstances, these methods don’t quite cut it. That’s where explosive demolition steps in.

How Does Explosive Demolition Work?

The main idea is to use explosives to swiftly and safely bring down a structure. Here’s a brief look at how the process works:

- Planning and Surveying: Before any explosives touch a building, demolition contractors assess the structure’s composition, condition, and proximity to surrounding buildings.

- Placement of Explosives: Experts determine which structural points, when destroyed, will result in the most efficient collapse. Charges are then strategically placed at these points.

- Safety Precautions: Aside from evacuating the surrounding area, safety barriers are established, and a detailed plan is laid out to handle any unforeseen circumstances.

- The Detonation: With a press of a button, the charges are detonated in a sequence.

- Cleanup: Post-collapse, the debris is carefully removed and sorted, often with a mix of manual labor and machinery.

Explosive Demolition Guide: The Three Methods of Demolition

While there are various ways to approach demolition, we’ll focus on three primary methods: Implosion (or Explosive Demolition), Deconstruction, and Mechanical Demolition.

1. Implosion (or Explosive Demolition)

Primarily, this technique is used when the structure is tall, like skyscrapers, or when other methods pose greater risks or inefficiencies. It’s also favored when the area surrounding the structure is densely populated, and traditional methods could cause more disruption.

It’s fast. An entire building can be brought down in seconds. Also, it can often be the safest way to ensure a building comes down without damaging neighboring structures in congested urban areas. However, this technique requires intensive planning. Misjudgments can lead to unintended damage.

2. Deconstruction

Instead of tearing down a structure entirely, the focus of deconstruction is on taking it apart piece by piece. This is preferred when there’s a desire to preserve materials for reuse. Deconstruction is a more deliberate and labor-intensive process, which might be chosen for historical buildings or when sustainability is a priority.

It’s the most environmentally friendly method. Materials like wood, bricks, and metals can be salvaged and repurposed. The downside is that it’s time-consuming and labor-intensive. Often, it’s more expensive than other methods because of the longer duration and specialized skill required.

3. Mechanical Demolition

When you picture a building being torn down with heavy machinery like bulldozers, cranes, or wrecking balls, you’re thinking of mechanical demolition. It’s the most common method used for smaller structures, like houses or low-rise buildings. It’s quick, efficient, and requires less specialized planning compared to implosions.

This technique is quick and cost-effective for most standard demolitions. However, it can be disruptive and cause noise and dust. It’s also not the best for material recovery, as it often leads to more waste compared to deconstruction.

What are the Explosive Materials Used in Demolition?

While the term “explosive demolition” might lead you to think of massive explosions and indiscriminate destruction, in reality, the process is much more controlled. The specific explosive materials used play an important role in ensuring the process is precise, predictable, and, above all, safe.

Role of Explosives in Controlled Building Collapses

Explosives are used to weaken key structural components, which cause the building to collapse inwardly in a predictable manner. The aim is always precision over raw power. Explosives are strategically placed to target essential supports and columns. By severing these critical points, the building’s own weight causes it to fall.

Modern demolitions use timed detonations. This sequencing ensures the building collapses inwards and minimizes risks to surrounding structures and people. Using the right amount and type of explosive minimizes collateral damage from shockwaves, debris, and noise.

Here’s a list of the types of explosive materials commonly used in the demolition industry:

- Dynamite

It is a highly stable explosive that’s been used for over a century. It consists of nitroglycerin absorbed into a base material, usually diatomaceous earth. Due to its stability and predictable nature, dynamite has been a go-to choice for many demolitions. Its controlled explosion is ideal for severing structural components without causing excessive collateral damage.

- C-4 (Composition C-4)

C-4 is a plastic explosive, which means it’s malleable and can be molded into various shapes. It’s much more powerful than dynamite by weight. Its plasticity makes it perfect for use in tight or unconventional spaces within a structure. It can be molded to fit around beams, columns, and other key structural components.

- TNT (Trinitrotoluene)

TNT is often recognized for its iconic red sticks. It’s relatively stable, resisting shocks and friction. While more commonly associated with military applications, TNT is sometimes used in demolition. It’s favored for its stable nature and consistent explosive properties.

- ANFO (Ammonium Nitrate Fuel Oil)

ANFO is a mixture of ammonium nitrate and fuel oil. It’s an industrial explosive often used in mining and construction. It is more economical than other explosives, especially for larger demolitions. It’s not as powerful as C-4 or TNT but can be used in larger quantities to achieve the desired effect.

Advantages of Using Explosives in Demolition

There are tangible benefits to using explosives in demolition, benefits that often make it the preferred choice for certain structures and environments:

Time-Efficiency

- Speedy Process: Unlike mechanical demolition or deconstruction, which can take days to weeks, a building can be brought down using explosives in mere seconds.

- Quick Turnaround: For projects on a tight schedule, explosive demolition ensures that the site is cleared rapidly.

- Minimal Disruption: Prolonged demolition work can be disruptive, especially in bustling urban areas. By using explosives, the actual demolition is over quickly.

Controlled and Predictable Results

- Precision Placement: Experts can place charges at specific structural points to ensure that the building collapses in a predetermined manner.

- Safety Protocols: Properly executed explosive demolitions are methodically planned to ensure maximum safety.

- Minimal Collateral Damage: With the right calculations and expertise, explosive demolitions can ensure that surrounding structures remain untouched and safe.

Economic Benefits

- Labor Savings: While there’s significant upfront planning, the actual demolition requires fewer man-hours compared to manual or mechanical methods.

- Equipment Savings: Unlike mechanical demolition, which requires various machines operating over extended periods, explosive demolition can be executed with minimal equipment.

- Site Prep Savings: Once explosives demolish a structure, the site is often easier and quicker to prepare for the next phase, be it construction or landscaping.

- Reduced Disruption Costs: In areas where prolonged demolition might slow down business operations or traffic flow, the quick nature of explosive demolition can save money in reduced disruption and associated costs.

Preparing for an Explosive Demolition

Explosive demolition is a meticulous process involving extensive preparation to ensure that the demolition is safe, precise, and effective.

Site Assessment and Structural Analysis

Before any explosive can be placed, a thorough understanding of the site and structure is crucial:

1. Site Survey

- Geographical Layout: The immediate surroundings of the building play a critical role in planning the demolition.

- Accessibility: Accessibility determines logistics, such as where equipment can be placed and how personnel can move around.

- Evacuation Zones: Determining which areas need to be evacuated or cordoned off is critical. This often involves coordinating with local authorities to ensure public safety.

2. Structural Analysis

- Blueprint Review: Studying the original blueprints of the building provides invaluable insight into its design, which highlights critical load-bearing components, materials used, and architectural nuances.

- Physical Inspection: Often, buildings set for demolition have undergone modifications after their initial construction or have experienced deterioration. A hands-on inspection helps identify these changes and assess their impact on the demolition process.

- Material Assessment: Different building materials react differently to explosives. Knowing the predominant materials, be it concrete, steel, wood, or masonry, is important to determine the type and amount of explosive required.

3. Historical Review

- Building History: Understanding past incidents, like fires or structural compromises, can influence the demolition approach. A building weakened by a previous event might require a different strategy than one in relatively good condition.

- Previous Renovations: Over time, buildings may undergo renovations that can change structural components or introduce new materials. Knowing these alterations is essential for accurate planning.

4. Environmental Impact Analysis

- Environmental Hazards: Before demolition, hazardous materials, such as asbestos or lead, must be identified and often removed to prevent their uncontrolled release during the explosion.

- Dust and Debris Control: The demolition team must plan for controlling dust and debris and consider factors like wind direction and the proximity of other buildings.

Evacuation and Safety Barriers

Safety means ensuring not just the security of the demolition crew but also the surrounding community and infrastructure.

1. Defining the Evacuation Zone

- Risk Assessment: This involves identifying potential risks associated with the explosion, such as flying debris, shockwaves, and dust clouds.

- Public Communication: It’s important to inform the public about the upcoming demolition, including details about the evacuation zone, timelines, and safety instructions.

- Rehearsed Evacuation: For high-risk demolitions, especially in densely populated areas, rehearsals might be conducted to ensure a smooth evacuation process on the day of the demolition.

2. Setting up Safety Barriers

- Physical Barriers: These can include fences, concrete barriers, or other structures that can deflect or block flying debris.

- Dust and Debris Screens: Special screens or curtains can be set up to minimize the spread of dust and debris, especially if there’s a risk to nearby structures or sensitive areas.

- Vibration Monitoring: To prevent damage to surrounding structures, vibration monitors can be installed to ensure that shockwaves from the explosion remain within safe limits.

Coordination with Local Authorities and Communities

Demolishing a structure, especially with explosives, requires close coordination with various stakeholders to ensure the process is seamless and safe.

1. Liaising with Local Authorities

- Permits and Approvals: This often involves submitting detailed plans, safety protocols, and environmental impact assessments.

- Emergency Services: Local fire, police, and medical services should be informed about the demolition schedule and any potential risks. Having emergency services on standby during the demolition is also good practice.

- Traffic Management: Roads surrounding the demolition site may need to be closed or rerouted. This requires collaboration with traffic and transportation departments to manage diversions and ensure smooth traffic flow.

2. Engaging the Community

- Public Meetings: Hosting informational sessions allows residents to ask questions, voice concerns, and learn about the demolition process.

- Real-time Updates: Providing updates via local media, social media, or community bulletins can keep everyone informed about the progress, especially if there are changes to the schedule.

- Feedback Channels: Setting up channels for feedback or complaints ensures that concerns from the community are addressed promptly.

The Demolition Process Step-by-Step

Demolition is about recognizing the steps that lead up to that moment. Every phase is crucial, with no room for errors.

Step #1: Drilling and Placing Charges

The precision with which charges are placed dictates the success of the entire demolition.

1. Drilling Points Identification

Based on the structural analysis, experts determine the most effective points to place the charges. The goal is to use the least amount of explosives to achieve the desired result.

2. Drilling Process

With the points identified, technicians drill holes to place the charges. During drilling, it’s essential to ensure no accidental sparks or other hazards arise, especially when working in older buildings with potentially flammable materials.

3. Placing the Charges

Once the holes are drilled, explosives are securely placed within. They must remain stable, with no risk of shifting or falling out. Each charge is then connected to a detonation system using wires. These wires lead to a central control point, where the sequence of detonations will be managed.

Step #2: Sequence Planning for Explosive Detonation

Proper sequencing ensures the structure collapses inward, which minimizes risks to surrounding areas.

1. Sequence Design

The primary goal of sequencing is to ensure that the building falls in on itself. This means detonating charges in such a way that central supports fail first. For taller structures, experts often design sequences that make the building collapse floor-by-floor, from the bottom up or vice versa, depending on the desired result.

2. Timing Precision

The difference between charges can be a matter of microseconds. Advanced detonation systems ensure that each charge goes off precisely when intended. Before the main event, technicians often run tests (without actual explosives) to ensure that the sequence operates flawlessly.

3. Final Checks

Before going live, the entire system is checked and double-checked for safety. This includes ensuring all charges are secure, all wiring is correctly connected, and no hazards are present. The demolition team stays in constant communication. Everyone should be clear on their roles and the sequence of events.

Step #3: Actual Detonation and Building Collapse

The moment of detonation is the culmination of weeks or even months of careful planning, coordination, and preparation.

1. Final Safety Check

Before initiating the detonation, it is important to ensure that the evacuation zone is clear of any unauthorized persons and that all safety barriers are in place. A clear line of communication among team members ensures everyone is in sync and aware of the impending detonation.

2. Initiating the Blast

A standard procedure is to have a countdown, which helps synchronize team members and alerts anyone in the vicinity. The explosives are set off from a secure location using a detonation system to ensure that the pre-planned sequence is followed.

3. Building Collapse

If everything goes according to plan, the building will collapse inward, minimizing the spread of debris and dust. Experts closely monitor the collapse to ensure it matches the planned trajectory. Any deviations can provide insights for future demolitions and indicate if immediate interventions are required.

Step #4: Post-Blast Safety Checks and Debris Removal

Once the dust settles, the site needs to be made safe and cleared for its next purpose, whether that’s new construction, landscaping, or something else entirely.

1. Immediate Safety Assessment

Explosions, even controlled ones, can sometimes ignite fires. Immediate checks are essential to ensure no smoldering fires are present. Nearby buildings or structures are examined to ensure the blast, or the falling debris hasn’t compromised them. Utility lines, especially gas lines, are checked for leaks or damage.

2. Debris Removal

Different types of debris (concrete, metal, glass, etc.) are sorted. Bulldozers, cranes, and other heavy machinery move in to help clear larger chunks of debris. Dust suppressants might be used to prevent dust from becoming airborne again. Additionally, care is taken to ensure harmful materials don’t leak into the environment.

3. Final Site Assessment

The ground is checked for stability, especially if new construction is planned for the site. The surrounding community might provide feedback, especially if there were any unforeseen disturbances. This feedback is invaluable for planning future demolitions. The demolition team gathers to discuss the operation’s successes and areas for improvement.

Explosive Demolition: Safety and Success Go Hand in Hand

Explosive demolition is a complex and intricate process grounded in extensive planning, expertise, and commitment to safety. The task requires the touch of seasoned demolition contractors to achieve desired outcomes while preserving the environment and ensuring community safety.

This is where we at Liberty Demolition can be of service. We offer a wide range of services, from residential to industrial demolitions. Our demolition contractors in Philadelphia are experts in ensuring proper implementation of safety, success, environmental protection, and client satisfaction. Whether it’s a selective demolition or a grand structure coming down, Liberty Demolition is armed with the tools, team, and determination to get the job done, all while championing eco-friendly waste management and recycling.

If you’re looking for a partner in demolition who values safety, environmental responsibility, and unparalleled client satisfaction, look no further. Let Liberty Demolition be your guide in transforming spaces and landscapes. Call us today!